Extruded tiles are manufactured and manufactured by pressing clay material through a mold to suit against pressing marble tile. However, pressing is a more common method used today. And after making green tiles, they dry up to pick up some of the moisture.

Granite tile is a very popular flooring choice due to its overall flexibility, strength and durability. Paint, natural acid, and scratch-resistant properties make it a structural favorite.

The restrictions are no longer limited to business spaces. Its popularity in residential and business homes has increased over the last decade, and now granite tiles have become beautiful, almost undamaged, breathtaking using modern technologies and design concepts.

- Granite Tile In Multi Color Choice For Foil

- Why Choose Granite Tiles For Flooring Work

- Granite tiles have been popular for many reasons

- exceptional durability and flexibility

- heat and acid resistant properties

- Neutral glasses with unique patterns

- Easy Maintenance It Cost Effective

- lifetime luminosity

- Quality is our top priority

We have been running successfully since 1998 just because of our quality and standard that we never compromise. We import natural stones directly from the production countries so its quality standards are maintained and distribute them to our market at the factory discount price. We provide transportation across the country with direct factory pricing.

We have the best and most unique collection of premium surface granite tiles with more than 100+ designs, colors (Blue Pearl, White Cashmere, Ubatba Green, Baltic Brown) and templates for choosing from all your floor decoration needs. It is available in many sizes, such as 12 x۱۲ ″, 16 x۱۶”, 18″ x۱۸” and 24 x۲۴.

After a wide and diverse set we choose and choose a set of types to give you your space, whether it’s in the kitchen, bathroom or hallway, a time-free and beautiful request.

Flooring tiles specifications

The floor tile is responsible for ensuring the mechanical properties and quality of the floor according to its specifications, performance and application. Therefore, designing these tiles is necessary for application in these applications. Floor tiles should have the following features:

- It must be a normal shape and size.

- It must be free from maze, cracks or defects.

- Must have been pretty burned, and have a color.

Tiles are a popular flooring material because they offer various advantages, especially for homeowners looking for a beautiful appearance that is durable and affordable. Floor tiles are made of a variety of materials, such as clay, rock, metals, and quartz. Each type of flooring has its own characteristics, features, and advantages. Choosing the right tile depends on the size of the project, the budget, the look and the specifications.

There are many types of tiles, materials, styles and colors. Offers all kinds of benefits and specifications. This article lists the types of tiles and their characteristics.

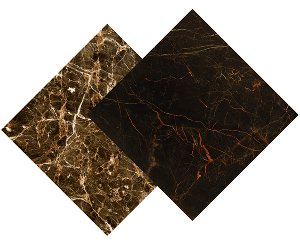

Granite tiles

Granite tiles are widely considered as one of the most durable natural tiles and freeze tiles due to the process of creation. It takes thousands of years for the granite to reach its final state, and it’s incredibly dense.

It is said that the strength of granite tiles is competing with diamond, which is actually used for cutting stone blocks from granite stone to granite stones in mines before becoming beautiful granite tiles.

The granite of tiles is becoming increasingly popular, and in addition to its natural beauty, granite has obvious advantages for homeowners. For example, Granite Tile Flooring is hard, durable and long.

Granite tiles are also easy to maintain and are available in a range of colors and finishes. Granite tiles are very diverse and always add a luxury allele to each project. Granite tiles are also popular due to high sensitivity, allergy and bacteria-resistant.

Granite tiles can be used inside or outside of the home in a polished or polished finish. Granite tiles are popular for floors, stairs, wall features and many other design elements. Tile granite (granite) is a well-known material used in projects to produce delicate, simple and quality removal.

Granite tiles manufacturing process

Granite stones are produced using volcanic rocks that have smooth surfaces. The smoothing process can also create hidden beauty in stone. However, beauty is just one of the advantages you can get from the granite floor tiles.

Therefore, in order to make granite tiles, the process of production from the source of granite stones is carried out by material removal process. The cutting equipment in this mine is by drilling holes into the mountain which is separated, running the cutting cable from the holes and feeding the cable like a bicycle chain to the equipment, which pulls the cable until it has destroyed the whole stone, and is free to leave the block standing.

The large block separated from the mining wall is more broken to smaller blocks suitable for transportation.

With the help of heavy cranes, these blocks are lifted and filled in trucks. These trucks deliver granite blocks to the site where it can be cut to steel parts using a machine called Band Saw or Marble Saw.

This granite stone has been transformed into a cube using clothing machine. It is then placed inside the band’s chainsaw to use a trolley to saw. Imported steel plates and diamond parts placed inside the band, help to cut hard granite block to parts or bar for tiles.

Granite tile specifications

Granite is a hard, crystalline, protruding stone that is made of molten magma and cools to the ground below. Granite is one of the hardest stones to be found, and it excels for used surfaces such as a kitchen bench.

Pro Note: Granite contains a variety of inorganic crystals, some of which may be acid sensitive. Therefore, it is essential to use the cleansers and resins properly.

Granite Tile Profile

- Polished or polished granite tiles with +/- ۰.۵mm tolerance are calibrated. The two sides are oriented towards the full right angle and the top edges of the micro are oblique.

- Granite as natural stone, changes to shade and pigment with one category is a natural occurrence and is accepted by industry as natural. This diversity adds unique beauty to the final level.

- It is recommended to consider 5 to 10% of additional material to the cover area depending on the installation style, in order to allow the pile to be used due to cutting tiles to fill corners and defects in natural stone tiles.

Your comment submitted.