If you have remodeled your kitchen or are just thinking about one, you must listen to all these interesting facts about quartz countertops. You know that choosing table top fabric can be the most difficult decision in the whole process. Kitchens and homeowners are different. so nothing is good 100 percent of the time.

That said, it’s easy to maintain and practical. You can’t do better than quartz counters. You may find yourself wondering about quartz counters in magazines or at your friend’s house. But how much do you know about quartz? Read on to learn more about this interesting resource.

1) Extremely durable and damage resistant.

Quartz is one of the hardest minerals in the world. And the composite stone used for the top floor retains most of its strength. This makes it the longest of the counter tops. when using quartz You don’t have to worry about wear and tear, such as scratching and heat resistance. also because it is not porous Therefore, it is resistant to germs, bacteria and mold. It helps with hygiene concerns

and although it is difficult But it is also easy. Therefore, it can be bent and adjusted to the desired counter shape. So, if you don’t use the board without slipping, that’s fine, because the cut is very clean. This means the seams are invisible and can be cut into the tiles!

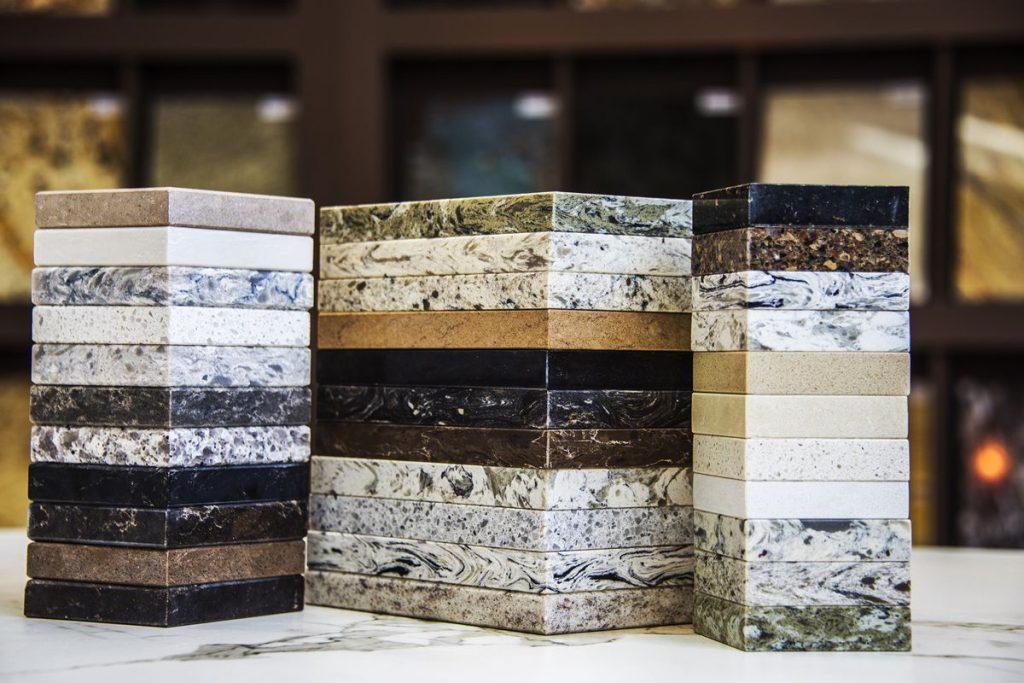

colored quartz countertop

2) It’s more than just rock.

Unlike other floor materials, quartz cannot be called a natural stone. By weight, it is about 90-95 percent quartz, the rest is resin, polymers, pigments and pattern scales. (If you consider volume without weight, the ratio is 65-35) The stone is made from natural quartz crystals that have been quarried, pulverized, and combined so that they can be combined with under extreme heat and pressure to the specified limit.

Although there are many quartz suppliers. But all the original materials come from the same place: the Italian company Breton, which has patented its design process since the 1970s. And if you care about the environment, that’s good news! The manufacturing process has low carbon emissions.

Do you know? Quartz is a popular material for kitchen countertops. But the popularity of bathroom floors continues to grow. Sealing is not required. Natural waterproofing is not easy to make and easy to clean. to wipe the face

3) There are few restrictions on viewing.

One of the downsides of quartz counters is the limitations in terms of shape and color variations it offers. Natural stones are considered to be the best choice for this purpose. over time But the damage dissipated. Now you have many options for your new counter.

color? A variety of styles are shown from the pigments included in the design process. Seriously, with bits of glass and metal added strategically throughout. You bet – polished, polished, polished, mounted and more. Advances in design have resulted in a wide variety of materials that can be made to look like natural stone, including:

4) Very easy to maintain

Can you see the shine on the new counter? for some materials this means using a sealer, top coat or primer. rather than quartz It is not porous as described above and does not require sealing. Also The cleaning effect is very low you will find.

Just mild soap and water, or a non-oily or non-abrasive solution. If you are willing to use A new in a short time. It is much more beautiful than washing! However, remember that heavy cleaning methods are not ideal. It is not recommended because it can damage the surface.

5) It has few weaknesses.

Even Superman is his kryptonite. Quartz countertops can be damaged if not handled properly. But it can be light. If you drop something heavy Try to loosen the adhesive, (don’t!) cut something on it without a cutting board. You should have a trivet to separate pans, frying pans, frying pans, etc.

Finally, they fade or glow under ultraviolet light. If it’s on the other side of the window that’s fine. Without a big window the light will come in. But if you are thinking about an outdoor kitchen. Consider other types of counters.

Simple counter installation

Does quartz look like the right material for your kitchen countertop? Contact us at Simple Kitchen today to find out how we can make it a part of your dream kitchen!

Approximately 10 percent of the material volume in quartz slabs is not stone. But is it a polymer or cement binder and the other 90 percent? Natural slag, marble and natural stone or waste from the recycling industry such as clay, silica, glass, glass, etc.

Yes, there may still be quartz – sometimes a lot. All these stone materials were mixed together and held together in strips. It gives the shape and pattern of the stone to the surface of quartz.

More precisely, it can be called manufactured stone or composite stone specification that accurately describes how these products are made. In fact, the industry is actively using the term engineered stone to describe this type of slab.

Bottom line: Quartz counters may contain more or less natural quartz. But without the solid quartz taken from the mines there are many other materials.

In 1963, the Breton company in northeastern Italy developed stone-making technology. which is licensed to operate under the Bretonstone® trademark.

Over 50 years later, Breton is still going strong and making quartz countertops. This process combines the mass of natural stone with a mixture of polymers, removes air, heats it and gives the material a panel that maintains the hardness and character of natural stone.

Bretonstone technology is licensed by more than 50 companies worldwide, including well-known quartz brands such as Silestone, Cambria and Caesarstone, although these manufacturers add their own flair and style to their slabs. They are still working on the original brevetto, or Breton’s patent. Some quartz countertops now include shards of glass and other glass. copper metal file and various ingredients of porcelain and marble It takes a lot of effort to create a mix that gives a unique look.

Cambria is the brand that represents most of the American market for quartz flooring. But few people know little about this American company: the company also has cheese.

The Davis family business, based in Eden Prairie, Minnesota, began in the 1930s as a dairy business that grew into the St. Peter Creamery Group, Le Sueur Cheese Company and Nicollet Food Products. stone business by selling quartz processing equipment

even today Davis affiliates supply about a third of a billion pounds of cheese to Kraft Foods every year.

The trade name Bretonstone has no relation to the word Breton, which refers to people from the British region of France. Bretonstone was developed more than 900 miles in Brittany in Castello di Godego, about 20 miles from Venice, Italy.

The Breton in Bretonstone is a handbag – a combination of bre (for brevetti, “patent”) and ton (for founder Marcello Toncelli’s surname).

Fiberboard as a building material is often misused. But you can say: no trees are cut to make fiberboard. Like engineered stone slabs, 90 percent of the stone material that makes up the base of quartz countertops is entirely waste from mining or other construction activities. Natural stone is not mined for use in quartz countertops.

Even resin with 10 percent quartz remaining is much lighter and less synthetic. The Breton trade term for this ingredient is “Bio-resin”, which refers to a mixture of artificial resins and resins derived from non-edible vegetable oils.

Homeowners may consider quartz on kitchen or bathroom counters. But quartz is mostly crushed in large quantities for items such as shopping malls, airports and Prada floors. You will no doubt walk on quartz slabs and never know.

Quartz has been in full swing since explorer Marcello Toncelli made small, hand-cast slabs, about 12 x 20 inches, which were cut and used for floor tiles. The request for the counter didn’t come until years later. Of course, even in the mid-70s, the board was only 50 inches long, which wasn’t a size that was worth putting on a counter.

There are many quartz-like products on the market. And quartz seems to be the most popular choice. One example is Caesarstone. Since “new” is not the current fashion category for consumers, Caesarstone has a “very new” category with offerings such as the Apple Martini, Blizzard, and Crocodile.

According to a report from the Freedonia Group, quartz miners continue to dominate quartz’s market share.

But this is fortunate for those who want to install the sand: lower prices due to lower demand. According to Freedonia, “college prices have dropped over the past decade due to increased resource availability.”

Since quartz countertops contain 10% resin, a hot pan or baking dish placed directly on the counter will produce white and dark colors. Quartz countertops are also expensive.

What is the difference between high quality and low-quality quartz?

The biggest difference between high quality and low-quality quartz countertops is the amount of resin used. Low quality quartz has 12% resin and high-quality quartz has 7% resin.

Is there a difference between quartz and quartz slabs?

Quartz is made by mixing other rocks with resin. while quartzite is a pure natural stone. Quartz, similar to marble or granite, is hard and often costs more than $10 per square foot.

Quartz countertops are very popular among interior designers and homeowners, especially for kitchens. Most people know that these are not natural stones, although most of them look like granite or marble. However, there are a few misconceptions about what quartz counters are other than what people do. Here are 8 interesting facts about quartz countertops that you may not know.

Quartz side panels are not necessarily quartz

You may be surprised to learn that not all quartz countertops are quartz. The correct term is “synthetic” stone because it contains other minerals besides quartz. The one thing that all quartz countertops have in common is the Bretonstone manufacturing process. The process does not indicate that quartz is present. The stones are marble, granite, or industrial waste such as silica or ceramics.

The top marks on the stone are made of quartz material as an important component, although not solid quartz. In most cases, the finished stone is 90% crushed quartz or quartz stone, and the rest is made of resin and pigment. The reason these companies use quartz is because it is very durable, so it is worth using it instead of other materials.

Engineered stones do the same thing

As previously mentioned, all processed stones use the Bretonstone process. It doesn’t matter what the brand is. They use this patented process to produce stone designed for paving. Other uses are under license from the Breton company, which introduced the technology in 1963.

The Bretonstone process involves mixing the materials together, compressing them to remove air, and heating them to fuse the materials together. If it is a solid mass, the manufacturer cuts the finished product into slabs similar to natural stone.

The company has licensed 50 companies worldwide to use the Bretonstone process. Among these licensees are well-known brands such as Cambria, Caesarstone, and Silestone. Each company adds something to the process to differentiate their products from their competitors, such as mirrors or metal parts. However, they all use the patent or “brevetto” of Breton technology.

Bretonstone has nothing to do with the Bretons

Bretons refer to the inhabitants of the Brittany region of France. But this does not apply to the patent process used to produce the manufactured stone. True, the name of the company is Breton, but it was founded by Marcello Toncelli a few minutes from Venice in Italy, in a place called Castello di Godego. The name of the company is a combination of the word “brevetti” and patents and “Toncelli,” in honor of the founder of the company, i.e. “Breton.”

Cheese and cakes

One of the most popular brands of engineered stone in the US is Cambria, which began manufacturing its signature quartz slabs in 2000 after acquiring a license and the necessary equipment. Today, many houses and businesses are supplied with the stones they made. However, they started teasing.

In the 1930s, the Davis family was deeply involved in the dairy processing industry, making cheese with Nicollet Food, Le Seur Cheese Company and St. Peter Creamery. Currently in Eden Prairie, the family continues to produce a million pounds of cheese a year for Kraft Foods, while producing their fair share of carpet tiles that homeowners can use to slice and serve their favorite cheese.

Quartz countertops are environmentally friendly

Most stones are made from waste materials, so they are a good example of the 3Rs of environmental protection: reduce, reuse and recycle. Although most top brands only use quartz, they do not use all quartz, so there is no mining involved in providing the quartz (or other natural stone) for the manufactured stone.

The resins and pigments used to bind and color the manufactured stones come partly, or entirely, from natural sources. So, it also helps to make the quartz easier. In particular, Biolenic resins from the Breton company are partly organic, as they are derived from vegetable oil of industrial quality.

My company has for decades been leading the market in both supply and export of quartz products to the entire countries around the world and is hence gently honored to have provided a link for all dear customers and traders to join us in world trade of quartz and have the best purchase ever in your life.

Your comment submitted.