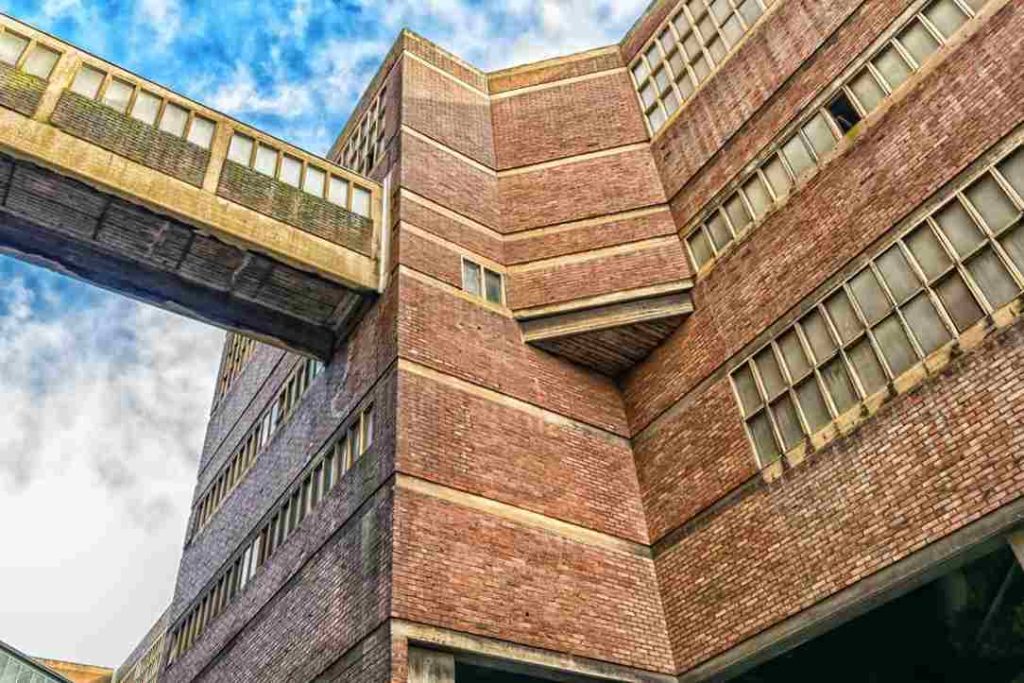

Here we will learn about the quality details of the stone used in the building, especially for the building facade.

The problem is whether the price of stone is the reason for the quality of the stone which is always present, not only in the subject of the stone, but also in all products.

My answer to this question is actually that I can’t say for sure that the factors that make the building height are the reason for the high quality of stone.

The cost of stone either goes up or down, depending on how it operates. Special quality buildings have special advantages and disadvantages; You can gain a more complete understanding of stone by recognizing the characteristics and benefits.

Quality of stone used for building facade:

The properties of strong resistance to weather conditions, color durability due to sunlight, high adhesion to mortar and various colors are all factors that have been considered in designing building facades.

On the other hand, travertine stones are generally considered to be the greatest possible quality in the industry.

According to the quality of the building stone used for floor:

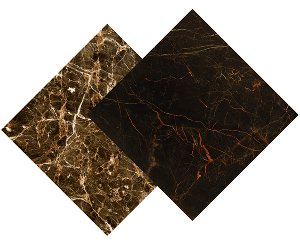

The selected floor stone should not have any holes in it, have adequate relative strength, various colors and patterns that are perfectly consistent with the building’s interior architecture, and are easy to clean without leaving the veins.

According to the parameters defined for the quality of the desired stone for this area, stones such as travertine are removed from the selections and you will be able to choose your desired stone for a suitable floor of the marble and chinese replacement.

Debate on Factors That Affect the Quality of Building Stones

You know that the quality of stones can be affected by different conditions. Color, quality, and processing methods are the three main criteria used to classify building stones.

When buying stones, take great care of its quality because there is no global standard for the grade or quality suitable for building stones. As we continue, we will look at each factor jointly.

Quarry

There is a large amount of overlap between different types of building stones. However, they are not identical in both quality and efficiency.

The first factor that distinguishes them is the type of mineral from which the stone is extracted. There are thousands of different types of mines in our country, and each one of them produces a wide variety of stones.

Now, depending on the area where the mine is located and the climate in that area, the mine has the potential to create a wide range of rocks, each of which has a unique set of features.

stone dimensions

The size of the building stone is another component that may affect the overall quality of the stone. If the rock measurement is accurate and it is cut in a proper way, that particular stone is considered a good quality.

People who work with stones are called rocks that have been precisely cut and have full dimensions as facades, or at least that which stones say by this description.

Stones are considered to be gonias if they have at least one criteria of high-quality stones. so that their status as high quality building stones can be created.

One of the most important criteria for determining the quality of building stones is the amount of water that can absorb.

The amount of water absorbed by building stones is a problem that seems significant. More water is absorbed by rocks with higher porosity. It is the case of dense rocks, through which no openings water can penetrate.

The higher the degree of building stone, the more water it absorbs, the less time per unit.

The rock’s ability to absorb water causes the stone to gradually decompose and disappear over time. Generally, the stones used for construction, such as travertine, have high porosity, but the marble stones have very low porosity.

One drawback of Travertine stone is that it cannot be used in flood-prone places; As a result, travertine stone should not be used in such places.

Beneath the stone and its smooth surface

Subjecting criteria is another criteria used to evaluate the quality of rocks. In the production and processing line, after each stone is cut, it is policed by a machine called a grinding machine.

This stone will have more luster if the Earth is wider and more. This particular type of stone is more reflective and gives beauty elegance to the structure it is ornamented.

It can be concluded from the statement that the degree of universality of rock is another important component in the quality of building stones that should be considered.

One of the most important criteria for determining the quality of construction is the lack of surface defects.

When buying a building, one of the factors that we consider is the type of stone that is used. Chipping, stone bending, or several visible scratches, all examples of what is known as surface defects on rock.

If every stone contains one or two of the aforementioned items, the stone is considered quality, and it cannot be sold to anyone else. Since stones with obvious defects may make your structure less than perfect, it is important to pay attention to this.

Stone used in the building and its processing type

How to process construction stones and the type of processing used can also be important factors that affect stone quality.

Resin, epoxy resin and ultraviolet light are tools used to make rocks.

The quality of stone is directly proportional to the quality of the material used in each stage of production. High quality building stones can be manufactured by careful processing.

Stone price, stone quality, and stone processing method can be significantly affected by factors such as stone resin, net, epoxy, and processing method.

“Construction projects in marble include packaging and shipping,” he said.

The final factor that determines the quality of stone as a building material is its packing and movement.

Even if the stone is made and processed with high quality, if the packing and shipping of the building stone is done incorrectly, the stone will be of low quality or even will be lost. This is true regardless of how the stone is produced and processed.

After each stage of production is completed in a stone factory, the stones are packaged using processes that are both correct and precise. In this industry, an even grinding technique is used to prevent stones from being damaged.

To avoid damage to a stone during transportation, he uses specialized tools and machinery.

A look at various factors that affect the overall quality of construction stones

The mine, from which natural building stones are extracted, is usually excavated using various techniques. like:

- Extraction performed using flashing blades

- parallel mining

- Extraction through the use of various types of raw materials

- Extraction Performed Using Coil

In fact, the factor that can determine the quality of building stones is whether or not the building stone has been cut in such a way that no cracks or cracks have been made in the rock cup, or in such a way that the amount of building stones has been reduced as much as possible.

After reading this article, you should have a better idea of the requirements to choose high quality stone for the project, so you should speak with reputable and well-known organizations and compare their rate and quality. Contact us if you have any questions.

Your comment submitted.